Process : Degreasing→ Acid or alkali etching→ Chemical polishing → Anodizing →Coloring or electrolytic colouring→ Sealing → Sealing and desmutting

Used for fingerprint resistant sealing after nickel containing sealing holes

1. Water soluble sealing agent for aluminum anodized film

2. Excellent fingerprint resistance and dirt resistance

3. After sealing, the water contact angle can reach over 90 degrees

Degreasing and cleaning

1.Free of phosphate, boric acid

2. Strong cleaning ability for grease, dirt, and oxide skin

Aluminum alloy alkaline etching process

1.Prevent bath solution from scaling, and easy to clean bath solution;

2.Good tolerance in aluminum ion in the bath, over 120g/L;

3.Low corrosion, less consumption of aluminum and sodium hydroxide;

4.Less bath dumping and the cost of wastewater treatment;

5.Over six months for bath cleaning, saving labor and time

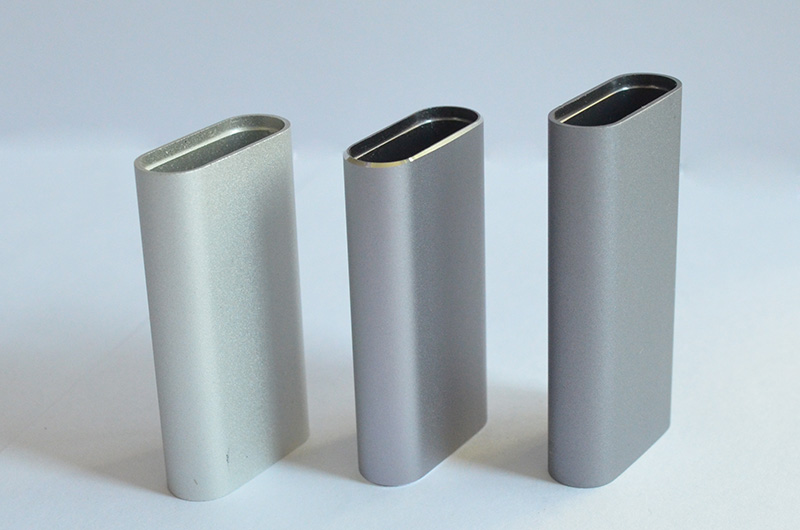

Aluminum matting and sanding treatment

1.Fine silver and white effect forms on aluminum surface;

2.Used under long service life, high aluminum ion concentration;

3.Free of phosphate and fluoride, and easy for wastewater treatment

Aluminum matting and sanding treatment

1. Improve the glossiness of aluminum while forming a sand surface

2.Adjust the finish with different ratio of phosphoric acid and sulfuric acid;

3.Free of hydrofluoric acid, fluoride salts and its substances

Desmutting and brightening used for die-cast aluminum

1.Quickly removes manganese, copper, silicon and other inert elements from the surface of die-cast aluminum materials

2.Remove surface stains, hanging ash, oxide skin, and black film from aluminum materials

3.Environmental protection does not contain phosphorus, chromium and other substances, no yellow smoke produced by nitric acid and nitrate

Desmutting and brightening used for die-cast aluminum

1.Quickly removes manganese, copper, silicon and other inert elements;

2.Remove stains, ash, oxide skin, and black film from the surface;

3. Free of phosphorus, chromium and nitric acid,no yellow smoke produced by nitric acid or nitrate

4.Produce a soft misty white finish

Used to remove surface dust after chemical polishing or alkali etching

1.Quickly removes manganese, copper, silicon and other inert elements;

2.Remove stains, ash, oxide skin, and black film from the surface;

3.Free of phosphorus, fluorine,chromium

4.Long service life, high ash removal efficiency, and fast speed