Process : Degreasing→ Acid or alkali etching→ Chemical polishing → Anodizing →Coloring or electrolytic colouring→ Sealing → Sealing and desmutting

Aluminum Alloy Chemical Polishing

1.The chemical polishing solution will not produce harmful substances such as nitrogen, oxygen, yellow smoke, chromium, nickel, etc;

2.Reduce the phenomenon of flow marks, drop marks and face flowers on the surface of the product after polishing

3.After polishing, the surface texture of the product is soft and uniform

Chemical polishing of aluminum alloy

1. Excellent chemical polishing anti material texture effect

2. After chemical polishing, the aluminum material has a strong metallic texture

3. No flow marks, no drop marks, no surface flowers and other phenomena

4. Up to 40g/L aluminum ions can still maintain the stability of the bath solutions

5. Environmental protection and non-toxic substances, free of nitric acid, chromic acid and nickel components

Aluminum Alloy Chemical Polishing

1.The chemical polishing solution will not produce harmful substances such as nitrogen, oxygen, yellow smoke, chromium, nickel, etc;

2.Good stability of the chemical polishing solution, easy maintenance, and no need to frequently adjust the tank;

3.The additive contains a brightening agent, which has a faster light emission rate than phosphoric acid and sulfuric acid chemical polishing solution;

4.Reduce the phenomenon of flow marks, drop marks and face flowers on the surface of the product after polishing

5.After polishing, the surface texture of the product is soft and uniform

Aluminum Alloy Chemical Polishing

1.The chemical polishing solution will not produce harmful substances such as nitrogen, oxygen, yellow smoke, chromium, nickel, etc;

2.The additive contains a brightening agent, which is faster than phosphate-sulfated liquid.

3.Reduce the phenomenon of flow marks, drop marks and face flowers on the surface of the product after polishing

4.High glossiness, can achieve mirror brightness, and can basically replace three acid chemical polishing

Aluminum Alloy Chemical Polishing

1.The chemical polishing solution will not produce harmful substances such as nitrogen, oxygen, yellow smoke, chromium, nickel, etc;

2.Reduce the phenomenon of flow marks, drop marks and face flowers on the surface of the product after polishing

3.After polishing, the surface texture of the product is soft and uniform

4.The additive has the function of anti-punching, anti-flushing and anti-tailing

Aluminum chemical polishing for phosphoric acid and sulfuric acid systems

1. Inhibit the bad effect of aluminum chemical polishing on the surface holes, cavities, and grooves of the product

2. Improve the uniformity of surface gloss of aluminum profiles after chemical polishing

Suitable for chemical polishing in phosphoric acid and sulfuric acid systems

1.Prevent bad effects of pores, holes, and grooves from chemical brightening

2.Improving the uniformity of gloss on chemical brightening;

3.Less evaporation of water in the high density solution

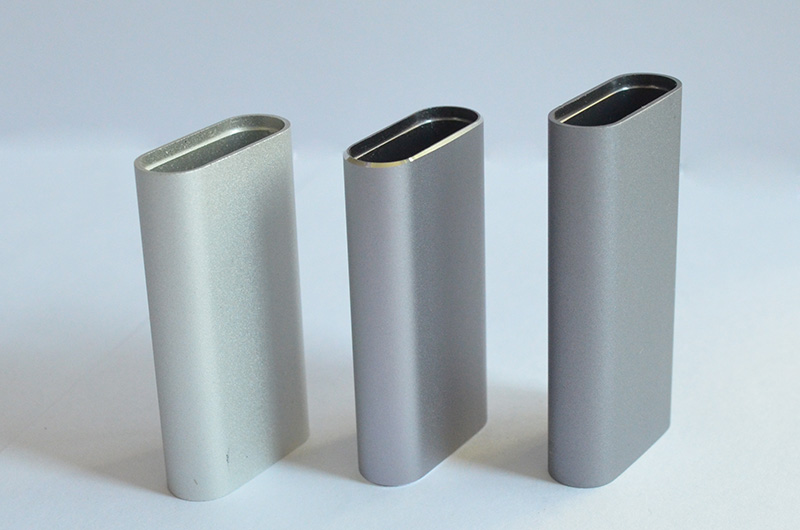

Anodizing film sealing for electronics products and high-end cosmetic cases

1.Good sealing effect, smooth and delicate surface finish;

2.Good sealing effect, surface fine and smooth