Electroplating and Chemical Platingof Aluminum

Explore the processes, challenges, and applications of aluminum surface treatment, electroplating and electroless plating from RTL Chemical.

Chemical conversion technology involves immersion or spraying chemical solutions to cause reactions on the surface of aluminum, resulting in the formation of a dense non-metallic conversion film. Unlike anodizing (which requires electricity), it has a simple process, low energy consumption, and is suitable for high-volume production.

Principle: Immerse aluminum in an acidic solution containing hexavalent chromium (Cr 6+ ) to form a chromate alumina-composite film.

Advantages:

Disadvantages:

Application:

Principle: Phosphate solution reacts with aluminum to form porous aluminum phosphate film

Advantages:

Disadvantages:

Application:

Principle: Replace chromium with titanium/zirconium salts, rare earths, or organosilicon to form a nanoscale conversion film.

Advantages:

Disadvantages:

Application:

Principle: Silane coupling agents react with hydroxyl groups on the surface of aluminum to form ultra-thin organic-inorganic hybrid films.

Advantages:

Disadvantages:

Application:

| Technology | Corrosion Resistance | Environmental Performance | Cost | Application |

|---|---|---|---|---|

| Chromating | ★★★★★ | ★ | Medium-priced | Military industry, aerospace industry |

| Phosphating Treatment | ★★ | ★★★ | Low price | Hardware components, auto parts |

| Chromium-free Conversion Treatment | ★★★★ | ★★★★★ | Medium-high price | Food packaging, 3C electronics |

| Silane Treatment | ★★ | ★★★★★ | Medium-high price | High-end coating, medical equipment |

Challenge: Hexavalent chromium is banned globally, and traditional processes are facing elimination.

Solution: Switch to chromium-free conversion films (e.g., zirconium titanium systems), or develop bio-based converting agents (e.g., phytic acid extracts).

Challenge: The conversion film does not match the subsequent spraying and adhesive processes.

Solution: Customized pre-treatment solution (such as silane+electrophoretic paint “golden combination”).

Challenge: Uneven film-formation in the grooves of complex workpieces.

Solution: Ultrasonic-assisted treatment, or the use of nano-scale film-formers agents to improve coverage.

From highly toxic chromates to green zirconium titanium films, from thick phosphating layers to nanoscale silane “invisibility coat”, chemical conversion technology has embarked on an evolutionary path in environmentally friendly and high-performance steel wires.

It makes our coke safer, our mobile phones more durable, and the electric cars we drive lighter – this invisible film is the gentle protection of technology for daily life.

https://rtlchemical.com/wp-content/uploads/2025/06/CHEMICAL-CONVERSION-TECHNOLOGY-OF-ALUMINUM.pdf

Explore the processes, challenges, and applications of aluminum surface treatment, electroplating and electroless plating from RTL Chemical.

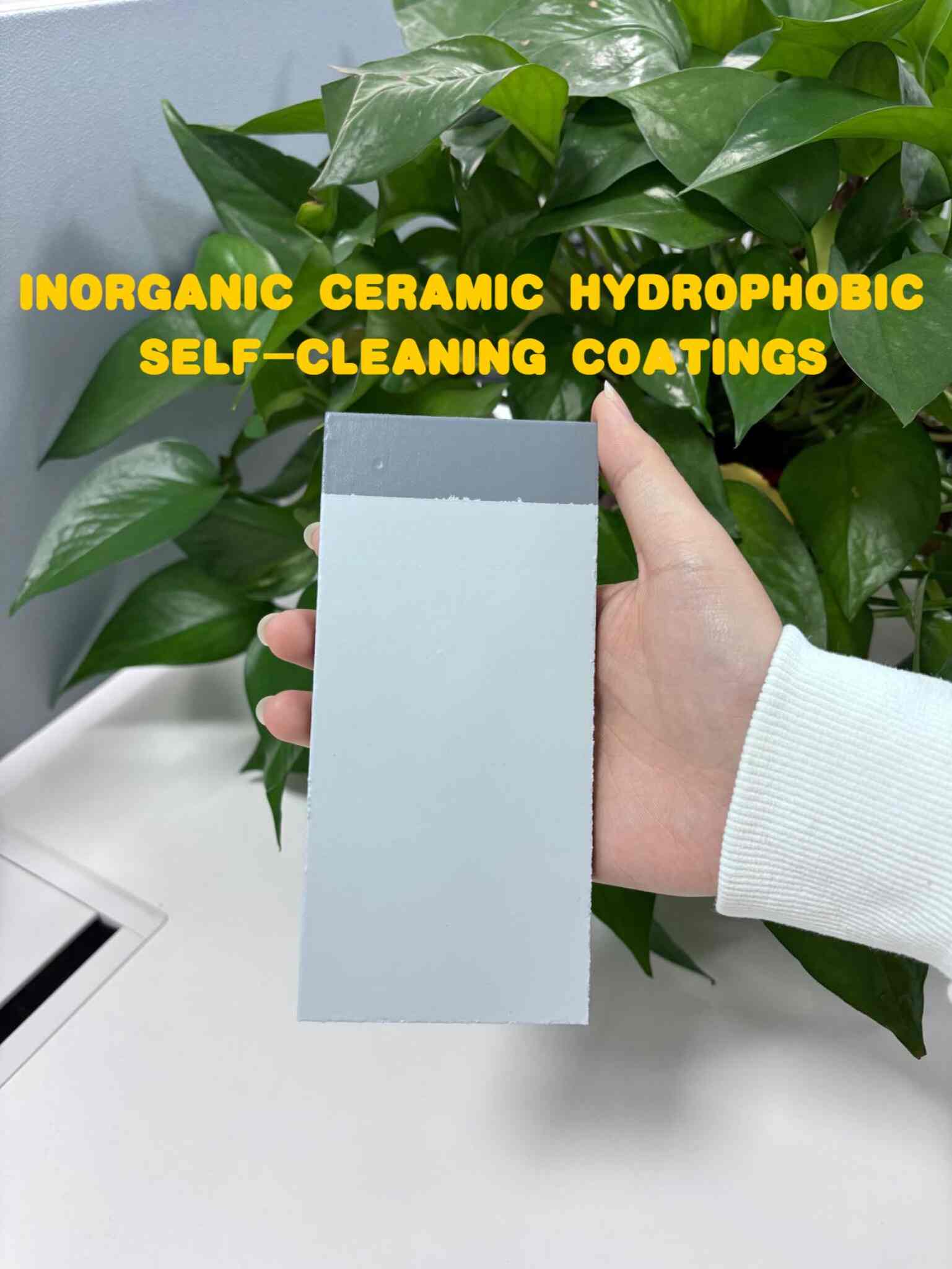

Explore NS2005 superhydrophobic coatings. Stain-resistant, self-cleaning, and durable, ideal for buildings, bridges, and more.