Our Products

RTL Chemicals caters to a wide range of industries, including automotive and electronics, with a commitment to cutting-edge technology and eco-friendly practices.

Our comprehensive product line ensures you find the perfect solution for your specific needs, delivering superior results while minimizing environmental impact.

3C Anodizing Industry

Chemical Industry Pre-treatment Series

T-Processing Series

Automotive Paint Series

We Are China’s Sole Agent for HMF-SealAL

As seen in our Alufinish Series

We also offer a revolutionary cold sealing process as part of our Alufinish Series of products: HMF-SealAL.

This heavy metal-free (HMF) technology delivers the speed and efficiency of traditional methods without the environmental burden. HMF-SealAL works on all surfaces and requires only a warm water rinse for completion.

Category

Aluminum Alloy Chemical Polishing Additive

Aluminum Alloy Chemical Polishing

Chemical polishing additive

Chemical polishing of aluminum alloy

Aluminum Alloy Chemical Polishing Additive

Aluminum Alloy Chemical Polishing

Aluminum Alloy Chemical Polishing Additive

Aluminum Alloy Chemical Polishing

Aluminum Alloy Chemical Polishing Additive

Aluminum Alloy Chemical Polishing

Anti-punching additives

Aluminum chemical polishing for phosphoric acid and sulfuric acid systems

Anti-punching Additive

Suitable for chemical polishing in phosphoric acid and sulfuric acid systems

Sealing agent-H

Anodizing film sealing for electronics products and high-end cosmetic cases

Fingerprint Resistant Sealing Agent

Used for fingerprint resistant sealing after nickel containing sealing holes

Eco-friendly degreasing agent

Degreasing and cleaning

Long-life Alkaline Etching Agent

Aluminum alloy alkaline etching process

Alkaline Sanding Agent

Aluminum matting and sanding treatment

Acidic Sanding Agent

Aluminum matting and sanding treatment

Die-casting Aluminum Desmutting Agent

Desmutting and brightening used for die-cast aluminum

Die-casting Aluminum Whitening Agent

Desmutting and brightening used for die-cast aluminum

Eco-friendly Desmutting Agent

Used to remove surface dust after chemical polishing or alkali etching

Phosphorus and nitrogen free neutralizing agent

Used to remove surface ash after chemical polishing or alkaline etching

Aluminum Oxide Film Surface Adjuster

Used for 3C anodizing

Inorganic Salt Dyes

Used for anodized dyeing products

Pre-dyeing Adjuster

For cast aluminum dyeing

Dyeing pH Stabilizer

Used to stabilize the dyeing bath

Dyeing And Mold Inhibitor

Used for dyeing bath

Sealing And Desmutting Agent

Used for desmutting after sealing

Releasing Agent

Used for rework and film removal of defective products after anodizing of aluminum materials

Alkaline Etching Additive

Used for alkaline etching bath

Dewaxing agent

Used for products containing polishing wax

Degreasing powder

Weak alkaline degreasing agent for aluminum and aluminum profiles

Acidic Sanding Agent

Sanding

Chromium-free Electrolytic Polishing Additive

Used for phosphoric acid and sulfuric acid two acid electrolytic polishing agents

Desmutting Agent

Used for removing floating ash on the surface after acidic electrolytic polishing and alkaline etching

Tin Salt Stabilizer

Suitable for electrolytic coloring products of anodized tin salt system

Tin Salt Stabilizer

Suitable for electrolytic coloring products of anodized tin salt system

Copper Salt Coloring Additive

Anodized copper salt system electrolytic coloring products

Electrolytic Coloring Agent

Suitable for anodized electrolytic coloring products

Electrolytic Coloring Agent

Suitable for anodized electrolytic coloring products

Sealing agent-N

Suitable for sealing after anodizing

Sealing agent-M

Suitable for sealing after anodizing

Sealing agent-H

Suitable for sealing after anodizing

Sealing agent-H

Suitable for sealing after anodizing

Paint Remover/stripper

Paint peeling of materials such as aluminum alloy, stainless steel, copper alloy, and iron

Paint Remover/stripper

Paint peeling of materials such as aluminum alloy, stainless steel, copper alloy, and iron

Paint Remover/stripper

Paint peeling of materials such as aluminum alloy, stainless steel, copper alloy, and iron

Water soluble paint remover

Used for anodizing E-coat system

Water soluble paint remover

Used for removing E-coat product racks

Dewaxing Water

Cleaning of aluminum alloy, stainless steel, and copper materials

Acidic Degreasing Agent

Cleaning of aluminum alloy, stainless steel, and iron materials

Alkaline Degreasing Agent

Cleaning of aluminum alloy, stainless steel, iron material, zinc alloy, etc

Acid Oil Removing Cleaning Agent

Cleaning of aluminum alloy, stainless steel, iron, and copper materials

Degreasing Agent

Aluminum alloy, stainless steel, iron and other multi-metal material cleaning

Cleaning Agent

Cleaning of aluminum battery shell and aluminum backplate

Cleaning Agent

Cleaning of aluminum battery shell and aluminum backplate

Desmutting Agent

Cleaning of iron and stainless steel materials

Mixed Brightener

Stainless steel, aluminum, zinc alloy, copper and other materials grinding

Grinding Fluid/Lapping Liquor

Grinding of stainless steel material

Aluminum Corrosion Inhibitor

Aluminum alloy cleaning

Cleaning Agent

Stainless steel material cleaning

Cleaning Agent

HMF process cleaning

Cleaning Agent

Copper cleaning and polishing

Cleaning Agent

Copper cleaning and polishing

Copper polishing additive

Copper cleaning and polishing

Copper Anti Oxidant Agent

Copper cleaning and polishing

Acid cleaning agent

Cleaning

Electrolytic polishing additive

Polishing

(Stainless steel) passivation solution

Passivation

Degreasing Agent

For aluminum Profile Coating Pre-treatment and oil removal

Acid Degreasing Agent

Used for coating pretreatment , degreasing /activation

Passivation agent

Used for aluminum profiles, as well as pre-treatment for coating and powder coating

Activator

Used for aluminum alloys and aluminum die castings, as well as pre-treatment for painting, powder spraying, and gluing treatment

Passivation Agent

Used for aluminum profiles, as well as pre-treatment for spray painting and powder coating

Degreasing Agent

Used for non corrosive and weakly alkaline degreasing agent for aluminum and its alloys

Activator

Concentrated liquid products for surface gloss and controlled corrosion of aluminum and its alloys

Chromium Free Passivator

Used for aluminum and its alloys, and can also be used for die-casting aluminum chromium-free passivation treatment products

Trivalent Chromium Passivator

Used for aluminum and its alloys, as well as for trivalent chromium passivation treatment of die cast aluminum products

Zinc-phosphating Agent M

Used for surfaces of steel ,especially on automobile bodies and parts

Zinc-phosphating Agent R

Used for surfaces of steel ,especially on automobile bodies and parts

High Phosphorus Chemical Nickel

Electroless nickel plating on metal or non-metal surfaces

Medium Phosphorus Chemical Nickel

Electroless nickel plating on metal or non-metal surfaces

Single Component Exterior Paint

Plastic parts such as bumpers, door handles, and spoiler covers for exterior decoration of cars, trucks, and buses

Two-component Exterior High-gloss Paint

Plastic parts such as interior and exterior bumpers, door handles, and spoiler covers of cars are coated with gloss varnish and colored paint

Single Component Exterior Paint

Plastic parts such as bumpers, door handles, and spoiler covers for exterior decoration of cars, trucks, and buses

Two-component Interior Paint

Single coat, multi coat, glossy primer for interior buttons, instrument center console, armrests, etc. of sedans

Two-component Interior Paint

Single coat, multi coat, glossy primer for interior buttons, instrument center console, armrests, etc. of cars

Two-component Interior High-gloss Paint

The interior buttons, instrument center console, armrests, and other parts of the cars are painted with a single layer of high gloss paint, and are coated with water-based primer

Degreasing Agent

Especially suitable for degreasing after rolling in the steel industry. It can also be applied to the cleaning of galvanized sheets

Finishing solution

Applied to the leveling process section of hot-dip galvanizing units, used for spray drying. It can improve the flatness and roughness of galvanized steel plates, thereby achieving better surface quality.

Trivalent Chromium Passivation Series

Chromium-free environmentally friendly multifunctional coating applied to coated steel plates, providing corrosion resistance, lubrication, coating and other multiple functions. Product series can be applied to hot dip galvanized, zinc aluminum magnesium steel plate, in line with the building board, home appliance board application requirements. Suitable for smooth coating and reverse coating construction.

Chromium Free Fingerprint Resistant Series

Chromium-free environmental protection multifunctional coating applied to coated steel plates, providing corrosion resistance, lubrication, coating and other multiple functions. The product series can be applied to galvanized, aluminized zinc, zinc aluminum magnesium steel plate, in line with the application requirements of home appliance board. Reverse roll coating method is recommended.

Chromium Resistant Fingerprint Series

Applied to aluminum-zinc plated steel plate, providing corrosion resistance, lubrication, weather resistance, chemical resistance and other multiple functions. Meet the needs of building board applications. Reverse roll coating method is recommended.

Chromium Free Passivation Series

Chromium-free environmental protection multifunctional coating applied to coated steel plates, providing corrosion resistance, lubrication, coating and other multiple functions. The product series can be applied to galvanized, aluminized zinc, zinc aluminum magnesium steel plate, in line with the application requirements of home appliance board. Reverse roll coating method is recommended.

Pre-treatment With Chromium in Color Coating

It is a hexavalent chromium pretreatment agent applied to the surface of zinc plating, aluminum plating zinc, aluminum plate and other substrates. It is suitable for roller coating process color coating line. The formula design can ensure that the pretreatment film and substrate and primer have excellent bonding force, and can meet the performance requirements of building board and home appliance color coating board at the same time. Suitable for forward coating and reverse coating process

Color Coated Chromium Free Pretreatment

Chromium-free pretreatment agent applied to the surface of zinc plating, aluminum plating zinc, aluminum plate and other substrates, suitable for roll coating process color coating line. The formula design can ensure that the pretreatment film, the base material and the primer have excellent bonding force, and meet the performance requirements of the home appliance color coating board.

Chromium Free Passivator

A chromium free environmentally friendly multifunctional coating applied to hot-dip galvanized steel plates (GI), commonly used for home appliance color coated plates to replace back paint coatings. Suggest using the reverse roller coating method for construction

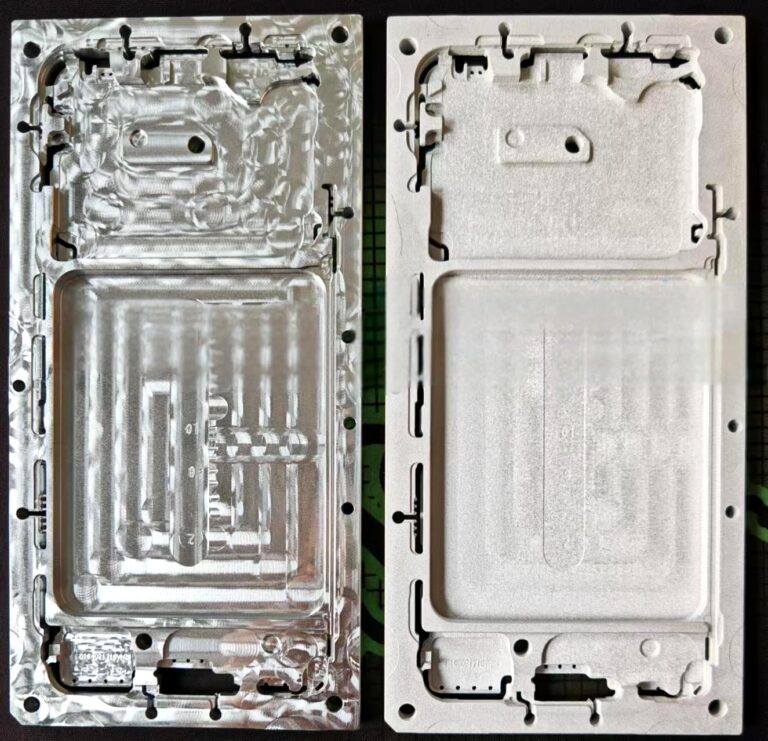

Acidic Sanding Agent

Aluminum alloy sand surface treatment before composite of 3C aluminum-plastic integrated structure.

T-process Electrolyte

Pre treatment of 3C aluminum-plastic integrated structure before composite.

T-process Product Adhesive

Pre treatment of 3C aluminum-plastic integrated structure before composite.

Titanium Etching Agent

Pre treatment of 3C titanium plastic integrated structure before composite/

Pretreatment of titanium plastic integrated structure before composite

T1-process Agent

Pre treatment of 3C titanium plastic integrated structure before composite/

Pretreatment of titanium plastic integrated structure before composite

T2-process Agent

Pre treatment of 3C titanium plastic integrated structure before composite/

Pretreatment of titanium plastic integrated structure before composite

Copper Surface Pickling Solution

Pre treatment before composite of copper and engineering plastics, application areas:

1. Chip packaging: The lead frame carrier for the internal circuit and external electrical components of the chip is integrated injection molded using copper and engineering plastic

2. New energy battery: functional plug, using copper and insulating plastic integrated injection molding

3. Copper enameled wire: The immersion coating of copper wire and insulating paint, as well as the exceptionally strong bonding between the insulating paint layer and copper wire

4. Printed circuit board: Copper coated circuits are cured like PP to produce double-layer or multi-layer circuit boards

Copper Surface Roughening Solution

Pre treatment before composite of copper and engineering plastics, application areas:

1. Chip packaging: The lead frame carrier for the internal circuit and external electrical components of the chip is integrated injection molded using copper and engineering plastic

2. New energy battery: functional plug, using copper and insulating plastic integrated injection molding

3. Copper enameled wire: The immersion coating of copper wire and insulating paint, as well as the exceptionally strong bonding between the insulating paint layer and copper wire

4. Printed circuit board: Copper coated circuits are cured like PP to produce double-layer or multi-layer circuit boards

Copper Surface Pre Immersion Solution

Pre treatment before composite of copper and engineering plastics, application areas:

1. Chip packaging: The lead frame carrier for the internal circuit and external electrical components of the chip is integrated injection molded using copper and engineering plastic

2. New energy battery: functional plug, using copper and insulating plastic integrated injection molding

3. Copper enameled wire: The immersion coating of copper wire and insulating paint, as well as the exceptionally strong bonding between the insulating paint layer and copper wire

4. Printed circuit board: Copper coated circuits are cured like PP to produce double-layer or multi-layer circuit boards

Copper Surface Film-forming Solutions

Pre treatment before composite of copper and engineering plastics, application areas:

1. Chip packaging: The lead frame carrier for the internal circuit and external electrical components of the chip is integrated injection molded using copper and engineering plastic

2. New energy battery: functional plug, using copper and insulating plastic integrated injection molding

3. Copper enameled wire: The immersion coating of copper wire and insulating paint, as well as the exceptionally strong bonding between the insulating paint layer and copper wire

4. Printed circuit board: Copper coated circuits are cured like PP to produce double-layer or multi-layer circuit boards

Film-forming Curing Agent

Pre treatment before composite of copper and engineering plastics, application areas:

1. Chip packaging: The lead frame carrier for the internal circuit and external electrical components of the chip is integrated injection molded using copper and engineering plastic

2. New energy battery: functional plug, using copper and insulating plastic integrated injection molding

3. Copper enameled wire: The immersion coating of copper wire and insulating paint, as well as the exceptionally strong bonding between the insulating paint layer and copper wire

4. Printed circuit board: Copper coated circuits are cured like PP to produce double-layer or multi-layer circuit boards

Phosphoric Acid

Suitable for anodized polishing bath

Sulfuric Acid

Suitable for anodizing polishing, Desmutting, anodizing, and electrolytic coloring

Nitric Acid

Suitable for chemical polishing bath and desmutting bath

Ammonium Bifluoride

Suitable for anodizing acid etching and film removal of defective productsSuitable for anodizing acid etching and film removal of defective products

Sodium Hydroxide

Suitable for anodizing alkali etching and film removal of defective products

Alfinal 204

Suitable for anodizing and electrolytic coloring products of aluminum and aluminum alloys

Steinex 22

Suitable for anodizing and electrolytic coloring products of aluminum and aluminum alloys

Alfisatin 358/1

Suitable for anodizing and electrolytic coloring products of aluminum and aluminum alloys

Alficolor Gold 605

Suitable for anodizing and electrolytic coloring products of aluminum and aluminum alloys

Alficolor 673

Suitable for anodizing and electrolytic coloring products of aluminum and aluminum alloys

Alficolor 693

Suitable for anodizing and electrolytic coloring products of aluminum and aluminum alloys

Alficolor 699

Suitable for anodizing and electrolytic coloring products of aluminum and aluminum alloys

Alficolor 680

Suitable for anodizing and electrolytic coloring products of aluminum and aluminum alloys

Alficolor Black 612

Suitable for anodizing and dyeing products of aluminum and aluminum alloys

Alfiseal 982/5

Suitable for sealing after anodizing

Alfiseal 961

Suitable for sealing after anodizing

Alfiseal 967/1

Suitable for sealing after anodizing

Alfiseal 968

On the basis of the above cold sealing 982/5 and hot sealing 961, an additional heat sealing 967/968 can be added to achieve alkali resistance pH 13.0, while meeting the stability of other properties requirements

Alfiseal 942

Suitable for sealing after anodizing

Alfiseal 975

Suitable for sealing after anodizing